-

Equipment

- Materials

- Quality Control

Screw Machines

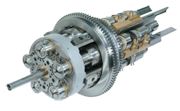

As our company expanded over the years, we’ve managed to acquire 21 small and large screw machines. The type of machines we use are for medium to high production runs from 1,000 to 1,000,000 parts, with single spindle and multi spindles up to 6 spindles. They are loaded with bar stock of varying diameters from 1/16” to 2 5/8” and profiles round, hexagon, square, and so on. Known for their fast cycle times, parts come out completed in seconds.Our screw machines are ready to accommodate your needs so contact us today!

17 Multi-spindle Screw Machines

- Capacity 1/16” To 2 5/8”

- BSA Acme-Gridley

- Davenport

- Greenlee

- New Britain

It’s the attachments that really make the difference. They enable us in most cases to make a complete part without the need to perform a second operation.

Attachments Capabilities

- Cross Drilling & Cross Tapping

- Slotting at the front and/or rear

- Multiple slots on same part @ 2x90° or 3x60°

- Individual spindle alignment capability to repeatedly place slots in relationship to material profile

- I.D. & O.D. , RH. & LH. Threading

- Pneumatic Thread Rolling for accurate & super smooth threads

- No-Pip Parting-off and rear deburring

- Broaching (ie. Hex shape for Allen keys)

- Knurling of straight, diamond, male & female patterns on diameter and face

- Precision Sizing reduces or eliminates the need for grinding

- Grooving Internal & External

- Circular tool holders

- Dovetail tool holders

4 Single Spindle Screw Machine

- Capacity 1/16” To 2 3/8"

- Brown & Sharpe 2B Ultramatic R/S

- MAS

Attachments Include

- Longitudinal Turning, 3rd & 4th Cross Slides

- Turrets 6 & 8 position

- I.D. & O.D. , RH. & LH. Treading

- ID. Chamfering from behind the part

- Broaching (ie. Hex shape for Allen keys)

- Knurling of straight, diamond, male & female patterns on diameter and face

- Grooving Internal & Externa

- Circular tool holders

- Dovetail tool holders

Maintenance Program

Our screw machine maintenance program is one of the best in the industry. We take great care in maintaining the quality and accuracy of our machines. As such, we do our own in-house adjustments, rebuilds, replacements, and upgrades of spindles and spindle bearings, thrust bearings, all clutches, cross slides, feed out mechanisms, and closing mechanisms.

Next, we have a dedicated tool grinding room where we grind our own step drills, circular and dovetail tools. Additionally, we maintain cutting edges to manufacturer specifications, including reamers, taps, drills, countersinks, slotting saws and endmills. Finally, we’re equipped with universal grinders with many attachments, surface grinders, universal cutter grinders, and precision drill & endmill sharpeners.

We service clients throughout North America, including those in Montreal, Toronto, Ottawa, Vanvouver, Calgary, Edmonton, Buffalo, Windsor, New York, Boston, Philadelphia, and many more.

If you would like more information, please contact our office.